Stainless Steel: Properties, Types, and Common Uses

Outline:

– Fundamentals: chemistry, passive film, key properties

– Families & Grades: austenitic, ferritic, martensitic, duplex, precipitation-hardening

– Performance: corrosion modes, temperature, hygiene, mechanical behavior

– Fabrication & Finishing: forming, welding, surface treatments, maintenance

– Selection & Lifecycle: application mapping, cost, sustainability, standards, conclusion

Fundamentals: What Stainless Steel Is and Why It Resists Corrosion

Stainless steel is an iron-based alloy that earns its name by forming an invisible, self-healing passive film. The essential ingredient is chromium: at roughly 10.5% or more, chromium combines with oxygen to create a nanometer-thin layer of chromium oxide that blocks further attack. Nickel, molybdenum, nitrogen, manganese, and controlled carbon further tune strength, toughness, and corrosion resistance. The beauty of stainless is not just its gleam; it is the quiet chemistry at the surface, constantly repairing after scratches or minor damage when oxygen is present.

From a physical standpoint, stainless steels are dense (about 7.7–8.1 g/cm³) and strong. Typical room-temperature yield strengths range from around 200–400 MPa for common austenitic grades to 450–1100 MPa for martensitic and precipitation-hardening families. Ductility is often generous, especially in austenitic grades, which simplifies forming complex shapes. Thermal conductivity is lower than carbon steel (austenitic stainless may be near 15 W/m·K, while carbon steel is commonly higher), which influences heat transfer in cookware, heat exchangers, and process lines. Many austenitic grades are nonmagnetic in the annealed state; ferritic and martensitic grades are magnetic. These distinctions matter when designing for sensors, magnetic clamps, or electromagnetic compatibility.

Corrosion resistance is not a single number; it depends on environment. Chloride-laden settings (seawater, road salts, swimming pools) challenge the passive film via pitting and crevice attack. Elevated temperatures alter oxide stability and can accelerate corrosion or embrittlement if the alloy selection is mismatched. The passive film’s resilience can be enhanced by alloying elements:

– Chromium raises general and oxidation resistance.

– Molybdenum improves pitting and crevice resistance in chlorides.

– Nitrogen boosts strength and resists localized attack.

In daily life, this chemistry translates into durability and hygiene. Smooth, stable surfaces harbor fewer residues and are easier to sanitize. Industrially, stainless allows components to endure cleaning cycles, sterilization, and temperature swings without frequent replacement. Its reliability is why you see it in food processing, pharmaceuticals, architecture, and transportation infrastructure—quietly saving maintenance hours and unplanned downtime.

Families and Grades: Austenitic, Ferritic, Martensitic, Duplex, and PH

Understanding the families of stainless steel helps you match material to task, rather than assuming one alloy fits all. The austenitic family (face-centered cubic structure) typically contains 16–26% chromium and varying nickel, sometimes with molybdenum and nitrogen. These grades are known for excellent formability, toughness down to cryogenic temperatures, and convenient weldability. Many are nonmagnetic in the annealed state and offer solid general corrosion resistance. Common workhorse grades in this family (such as those with 18% chromium and 8–10% nickel, and molybdenum-bearing variants) appear in sinks, tanks, fasteners, and chemical equipment.

Ferritic stainless steels (body-centered cubic) contain chromium (roughly 11–30%) with little or no nickel. They are magnetic, typically less expensive than nickel-bearing alloys, and resist stress-corrosion cracking better than many austenitics. Ferritics are suitable for automotive exhausts, appliances, and cladding where formability and moderate corrosion resistance are sufficient. Martensitic steels, with higher carbon and moderate chromium, can be heat treated to high hardness and wear resistance. They are chosen for knives, turbine blades, and mechanical components where edge retention or abrasion resistance matters, though their corrosion resistance is generally lower than austenitic or duplex options.

Duplex stainless steels mix austenitic and ferritic phases, delivering a blend of strength and chloride resistance. They typically carry around 21–26% chromium, with modest nickel and often molybdenum and nitrogen. Yield strength can be roughly double that of common austenitic grades, enabling thinner walls and lighter structures without sacrificing durability. They handle brackish water, desalination equipment, and marine structures with notable efficiency. Precipitation-hardening (PH) stainless steels introduce elements and heat-treatment schedules that form fine precipitates, providing high strength with decent corrosion resistance—valuable for aerospace, springs, and precision components.

When comparing grades, think in terms of trade-offs rather than absolutes:

– Austenitic: Outstanding formability and hygiene; reliable general corrosion resistance; nonmagnetic in many cases.

– Ferritic: Magnetic; cost-conscious; decent resistance in mildly aggressive environments.

– Martensitic: Heat-treatable to high hardness; chosen for wear and edges.

– Duplex: High strength and robust chloride performance; balanced properties.

– PH: Tailored high strength with corrosion resistance suitable for specialized parts.

Selecting among these families involves environment, strength target, forming needs, and total cost of ownership. The “right” grade aligns with the medium (water, acids, chlorides), the temperature profile, and the fabrication plan.

Performance in Real Environments: Corrosion Modes, Temperature, and Hygiene

Stainless steel’s reputation is earned in the field, where water chemistry, temperature, and mechanical stress conspire to expose weaknesses. General corrosion is seldom problematic in neutral atmospheres, but localized corrosion can be decisive. Pitting occurs when chlorides breach the passive film at microscopic imperfections; tiny pits grow into deep cavities that are hard to detect until late. Crevice corrosion forms in shielded zones—under gaskets, deposits, or lap joints—where oxygen is limited. In mixed-metal systems, galvanic effects can accelerate attack on the less noble partner when they share an electrolyte.

Engineers often estimate resistance using indexes that account for chromium, molybdenum, and nitrogen—the elements that shore up the passive film in chloride service. For example, molybdenum-bearing austenitic grades generally pit less readily than their molybdenum-free counterparts, and duplex materials often raise the bar further. Temperature matters. Many alloys that behave well in cool seawater may struggle as temperature rises; even a 10–20°C increase can tilt the balance. In hot acidic or reducing environments, nickel additions usually improve performance. In oxidizing acids, high-chromium alloys may do better. Matching alloy to chemistry is the heart of stainless selection.

Mechanical performance also shifts with environment. Chloride stress-corrosion cracking can affect strained austenitic stainless at elevated temperatures; ferritic and duplex grades show greater resistance. At low temperatures, austenitic steels retain toughness better than ferritics or martensitics, making them suitable for cryogenic tanks and piping. Heat resistance is another strength: many grades maintain scale resistance in air up to 800–1100°C, depending on composition and exposure time, though creep properties vary and must be checked for long-term loads.

Hygiene and cleanability are practical advantages. Smooth, corrosion-free surfaces limit biofilm formation and ease sanitation. That’s why stainless dominates in commercial kitchens, dairies, breweries, and pharmaceutical suites. Still, success depends on design details:

– Avoid tight crevices and dead legs that trap liquid.

– Slope surfaces for drainage and access for cleaning.

– Use compatible fasteners and gaskets to minimize galvanic or crevice risks.

In short, performance is a conversation between alloy, environment, and geometry. Get those three aligned, and stainless becomes a remarkably dependable partner.

Fabrication, Finishing, and Maintenance: Getting the Most from the Alloy

Stainless steel rewards careful fabrication. During forming, its work-hardening behavior—especially in austenitic grades—means strength can increase as the material is bent or drawn. This is helpful for stiffness but requires appropriate tooling and intermediate anneals for deep work. Ferritic grades can be less forgiving in severe stretch forming but respond well to bending and roll forming when radii and speed are controlled. Martensitic and PH grades require attention to heat treatment sequences to achieve target properties without distortion.

Welding quality directly affects corrosion resistance. Excessive heat input or slow cooling can cause sensitization in susceptible grades, where chromium carbides precipitate at grain boundaries and locally deplete chromium from the matrix. Solutions include using low-carbon variants, stabilized grades (with titanium or niobium), appropriate filler metals, interpass temperature control, and post-weld cleaning. After welding, restore the passive film with thorough removal of heat tint, slag, and iron contamination via pickling or mechanical finishing, followed by proper rinsing. Surface iron embedment from carbon-steel tools can seed rust; dedicated brushes and abrasives for stainless are a small investment that pays off.

Finishes influence corrosion resistance and aesthetics. Mill 2B provides a smooth, cold-rolled surface; bright-annealed yields mirror-like reflectivity; brushed or satin finishes hide fingerprints and scratches in architectural settings; bead-blasted or matte textures tone down glare. In aggressive environments, smoother finishes generally reduce sites for crevice initiation and biofouling. For food and pharma installations, low-roughness surfaces help cleaning validation and microbial control.

Maintenance is straightforward when done right:

– Clean with mild detergents or dedicated stainless cleaners; rinse thoroughly.

– Avoid steel wool or chloride-heavy cleaners that can damage the film.

– Remove deposits and discoloration promptly to prevent under-deposit attack.

– Inspect gaskets and joints to limit crevice formation and stagnant pockets.

Good design and finishing lower life-cycle costs. Rounded corners, accessible welds, and drainage paths make washing easier and reduce chemical demand. With these practices, stainless parts preserve their appearance and performance for years, turning one-time fabrication effort into long, reliable service.

Applications, Selection, Cost, and Sustainability—A Practical Conclusion

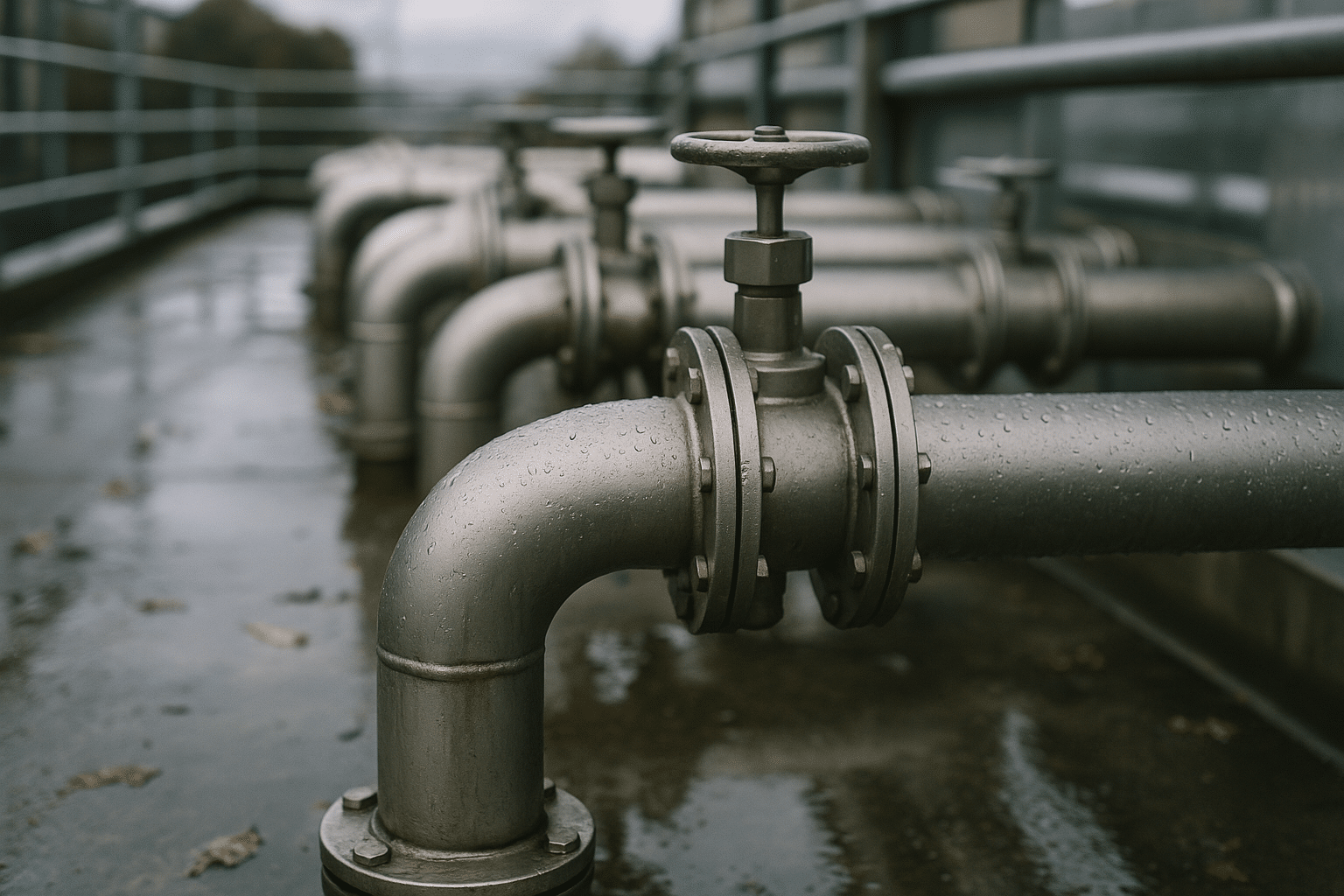

Stainless steel shows up wherever corrosion, cleanliness, and resilience intersect. In buildings, it anchors façades, handrails, roofing, and fasteners that must endure weather and pollution. In water and wastewater treatment, duplex grades provide strength and chloride tolerance for tanks, screens, and piping. Food and beverage facilities rely on austenitic grades for tanks, conveyors, and clean-in-place loops. Transportation uses stainless for exhausts, cargo tanks, and structural details that face road salts. The breadth is large because the palette of alloys allows tuning to each task.

Selection often benefits from a simple decision path:

– Identify the environment: fresh water, seawater, acids, alkalis, sterilants, temperature.

– Define mechanical needs: strength, toughness, wear, weight, thickness.

– Consider fabrication: forming depth, welding method, finishing requirements.

– Map cost across the lifecycle: purchase, installation, cleaning, downtime, replacement.

– Check standards and availability: product forms, codes, and regional supply.

On cost, stainless can carry a higher upfront price than carbon steel, driven by alloying content and processing. Yet total cost of ownership frequently narrows the gap. Fewer paint cycles, lower downtime, and longer service intervals can offset initial spend—especially in corrosive settings or where hygiene is regulated. Material prices fluctuate with nickel, molybdenum, and energy markets, so evaluating alternatives (for example, molybdenum-bearing vs. molybdenum-free grades) is sensible when performance margins allow.

Sustainability is a genuine strong suit. Stainless is fully recyclable, and industry sources report average recycled content often near or above 50–60%, with many products reclaimed at end-of-life. The passive film means fewer coatings and solvents, reducing chemical load during maintenance. Long service life means less frequent replacement and less waste. Responsible design further improves outcomes: choose adequate thickness to prevent through-wall corrosion, specify smooth finishes where hygiene matters, and plan for disassembly to simplify recycling.

Standards provide a shared language for quality and substitution. Specifications for plate, sheet, bar, and pipe define chemistry, mechanical properties, and delivery conditions, ensuring that a grade purchased in one region behaves predictably in another. Consulting these alongside corrosion data and fabricator input reduces surprises during commissioning.

Conclusion for practitioners: Stainless steel is not a single solution but a family of reliable options. Match alloy to environment, design out crevices, treat welds with respect, and think in lifecycle terms. Do that, and stainless will deliver a rare combination of durability, cleanliness, and visual appeal—quietly earning its keep year after year.